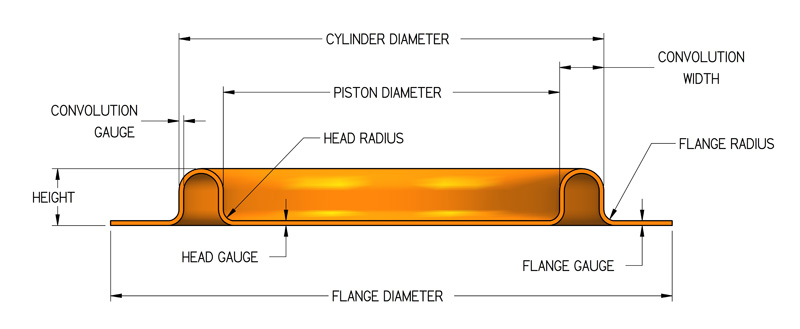

Type FC Diaphragm

General Description

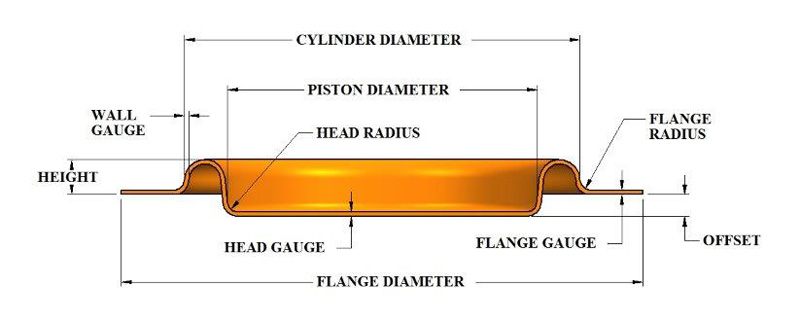

In this style, the piston and the flange are moulded on the same plane. The benefit of this style is that the handwork of forming the convolution is eliminated, which greatly reduces the assembly time. This would be of importance in high volume applications. The drawbacks to this type of diaphragm are: a built-in spring rate due to the moulded-in convolution, which must be considered during the design stage and a limited stroke-to-bore ratio. To improve this ratio, an offset preconvoluted diaphragm can be designed (see FC Offset figure at bottom of page). In this shape, the piston head and flange are moulded offset to each other, thereby putting all the additional stroke capabilities on one side of the convolution. This provides a longer stroking diaphragm, which still maintains the assembly ease of a preconvoluted diaphragm.

For Product Inquiries & Information Only: